Contractorship

All-in-one large-scale construction projects

Contractorship

We specialize in modern large-scale construction undertakings resilient to fads and changing trends, designed to be future-proof, ahead of their time, and made to last.

We specialize in modern large-scale construction undertakings resilient to fads and changing trends, designed to be future-proof, ahead of their time, and made to last.

Our unique business model lets us provide an extensive range of services for all kinds of investment projects, from design and obtaining building permits to construction and obtaining certificates of occupancy. This is something project owners who require end-to-end customer service to save time on handling formalities and searching for individual trade contractors value greatly.

We skillfully combine form and function, aesthetics and practicality. Our design efforts aim to foresee and take the possible scenarios for the current and future use of the facility designed into account in case of a change in business orientation.

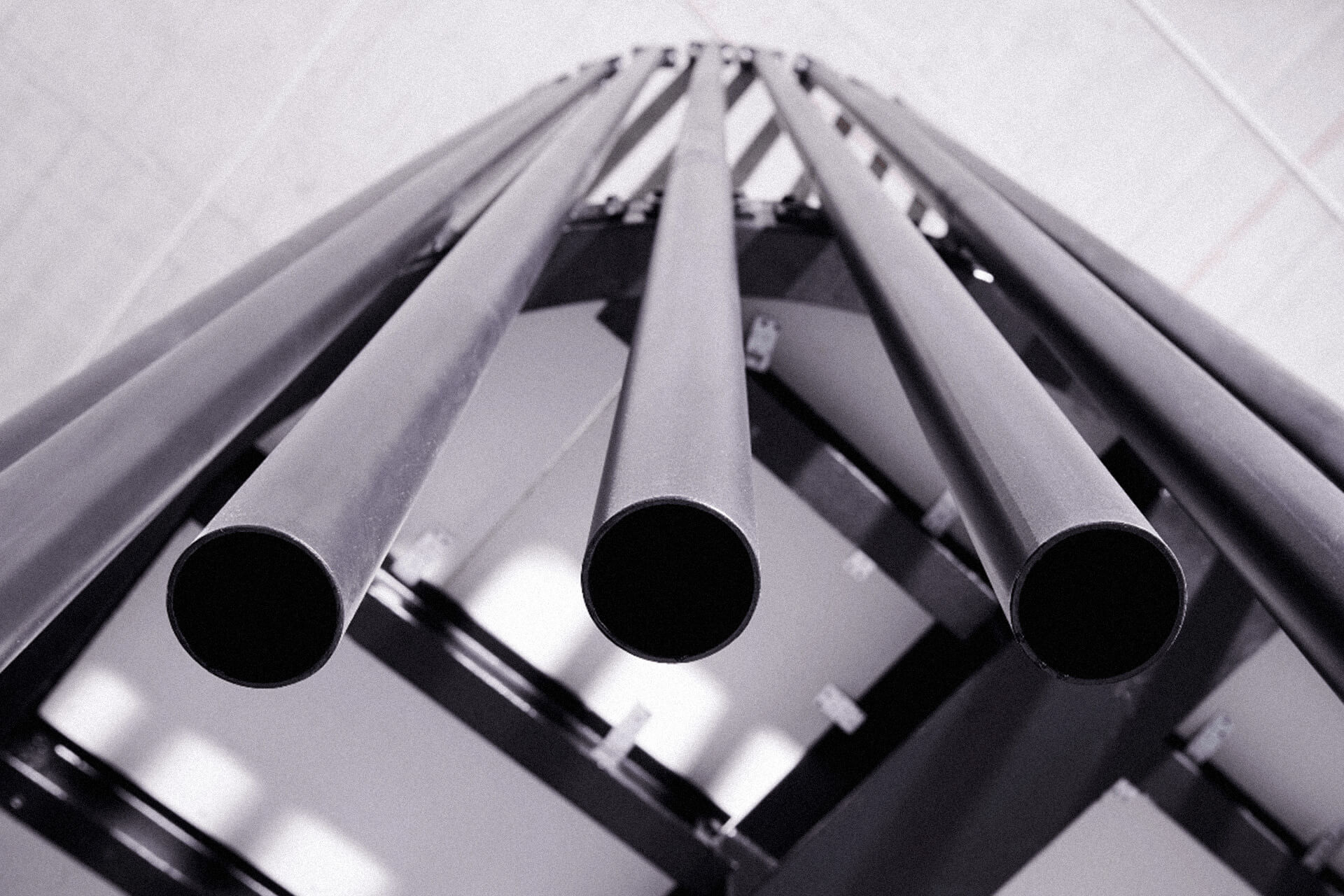

We have our own manufacturing plant, which produces more than a hundred tons of steel structures for our clients each month. We manufacture precast units and deliver finished elements to the construction site, erecting buildings according to design specifications.

We specialize in precast modular construction, which involves manufacturing and constructing Modular System Buildings formed of framed partition systems. Compared to traditional solutions, this technology reduces the construction time by half.

At the construction stage, we reach for modern technological solutions that enable us to minimize the risk of errors in the construction process and monitor the construction parameters of the constructed facility once it’s put into use. We work with partners specializing in AI-based technologies applied in the operational layer of manufacturing and warehousing projects.

We manufacture precast steel structures and deliver them to the construction site. When applying different manufacturing methods, we go for those that optimize the consumption of raw materials and time-consuming labor — and minimize production costs and the impact on the natural environment. We act responsibly and efficiently, always making sure that the assembly and delivery of precast units are up to the highest quality standard and that each stage of work is completed on time.

The components that we manufacture in our facility meet the requirements of stringent European standards such as EN ISO 3834-2, EN 1090-2, classes EXC1-EXC3 and EN 1090-1, and bear a CE marking – ZA.3.2 and ZA.3.4, verified periodically by professional industry auditors from independent certification bodies.

The construction elements we supply are corrosion-treated, fire-protected, hot-dip galvanized, and hydrodynamically paint-coated, up to corrosion protection classes C1-C5-M and fire resistance classes R15-R240.

Our Customer Service Center is available Monday through Friday from 8.00 am to 4.00 pm.